What to Anticipate From Quality Commercial Refrigerator Repair Services

What to Anticipate From Quality Commercial Refrigerator Repair Services

Blog Article

Making Best Use Of Efficiency: Commercial Refrigeration Repair Techniques for Cost-Effective Solutions

Assessing Refrigeration System Performance

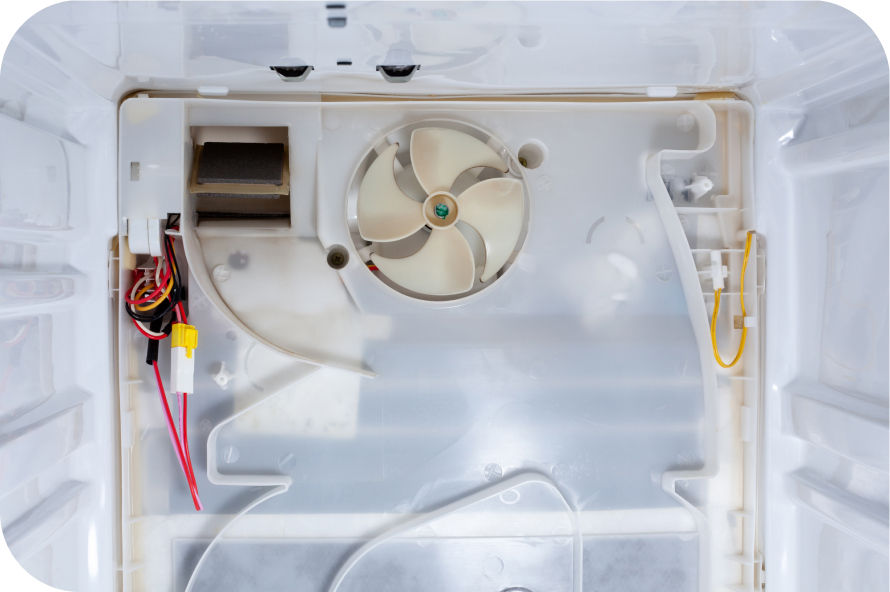

To successfully review the performance of a commercial refrigeration system, it is crucial to perform extensive evaluations of its crucial elements and operational criteria. The initial step in evaluating system performance is analyzing the performance of the compressor. The compressor plays a crucial function in preserving the preferred temperature within the refrigeration system. Problems with the compressor can lead to poor air conditioning, temperature level variations, and boosted power consumption. Carrying out routine evaluations and performance examinations on the compressor can assist identify possible issues early and prevent costly malfunctions.

In addition, reviewing the condenser and evaporator coils is paramount. Clogged or dirty coils can considerably impact the system's efficiency by preventing warmth transfer processes. Cleaning up the coils consistently and making sure proper air flow around them can optimize the system's air conditioning ability and reduce energy consumption. Checking cooling agent levels and pressures is also essential in analyzing system performance. Reduced refrigerant degrees or irregular pressures can suggest leakages or malfunctioning parts that require prompt attention to stop system failures and costly fixings. By methodically assessing these functional criteria and key components, organizations can ensure their business refrigeration systems run at peak efficiency levels, decreasing downtime and making the most of power effectiveness.

Carrying Out Preventative Maintenance Measures

Evaluating the performance of a commercial refrigeration system provides valuable understandings that can educate the execution of preventative upkeep procedures important for sustaining optimal functionality and durability. By establishing a routine maintenance schedule, refrigeration systems can run successfully, minimizing energy consumption and decreasing the threat of unforeseen break downs. Ultimately, spending in preventative maintenance measures is an affordable strategy that helps organizations prevent expensive repairs and downtime, making certain continual and trustworthy refrigeration system efficiency.

Identifying Common Refrigeration Issues

One of the key aspects in keeping commercial refrigeration systems is promptly identifying usual concerns that may occur throughout their procedure. Additionally, damaged gaskets on doors, resulting in air leakages, can cause the refrigeration system to function more challenging to preserve the preferred temperature. By without delay identifying and dealing with these typical article source refrigeration issues, companies can make sure the reliable procedure of their systems and minimize costly repair work.

Making Use Of Energy-Efficient Fixing Methods

When taking into consideration industrial refrigeration repair work, applying energy-efficient methods is paramount to enhancing the system's performance and minimizing operational expenses. Among the crucial strategies in accomplishing power effectiveness is making certain that the refrigeration system is correctly kept. Regular upkeep, such as cleansing condenser coils, looking for cooling agent leaks, and calibrating temperature level setups, can substantially boost energy effectiveness.

Another energy-efficient repair work strategy is upgrading to high-efficiency elements - Toronto commercial refrigerator repair. By replacing older, less effective components with energy-efficient alternatives, such as ECM fan electric motors or LED lights, companies can minimize power consumption and lower utility prices. In addition, mounting programmable thermostats and power monitoring systems can assist control temperature levels better, preventing unnecessary power use

In addition, enhancing the system's insulation and sealing any kind of leakages can likewise add to energy cost savings. Appropriate insulation assists maintain constant temperature levels within the refrigeration device, reducing the work on the system and improving overall efficiency. By incorporating these energy-efficient repair work techniques, companies can not only decrease their environmental impact but also achieve lasting price financial savings.

Optimizing Refrigeration System Life-span

To guarantee the long life and ideal efficiency of commercial refrigeration systems, read here maintaining energy-efficient fixing techniques is vital, with a focus currently changing towards optimizing the refrigeration system lifespan. Optimizing the life-span of a refrigeration system includes positive maintenance, timely fixings, and adherence to supplier guidelines.

In addition, spending in high-grade components and parts throughout fixings and substitutes can boost the longevity of the refrigeration system. By focusing on aggressive upkeep and making use of high quality elements, companies can optimize the lifespan of their commercial refrigeration systems, eventually reducing downtime and operational prices.

Verdict

Finally, by regularly examining refrigeration system efficiency, executing preventative upkeep actions, determining typical refrigeration concerns, utilizing energy-efficient repair service strategies, and optimizing the system's life expectancy, organizations can maximize efficiency and decrease prices associated with business refrigeration repair. These cost-efficient solutions assist to guarantee that refrigeration systems operate at peak performance, eventually bring about raised efficiency and profitability for organizations in the long run.

When considering industrial refrigeration fixing, implementing energy-efficient methods is extremely important to optimizing the system's performance and minimizing functional prices.To guarantee the durability and ideal efficiency of business refrigeration systems, maintaining energy-efficient repair work methods is necessary, with an emphasis currently shifting towards taking full advantage of the refrigeration system life-span. Maximizing the life-span of a refrigeration system involves proactive maintenance, timely repairs, and adherence to producer guidelines.

Report this page